|

|

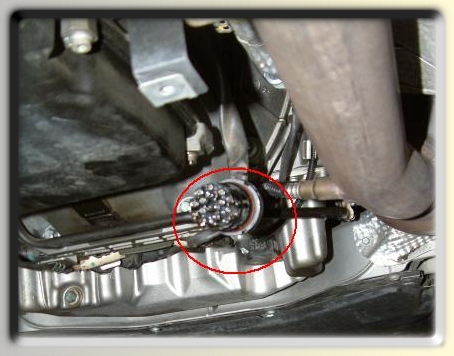

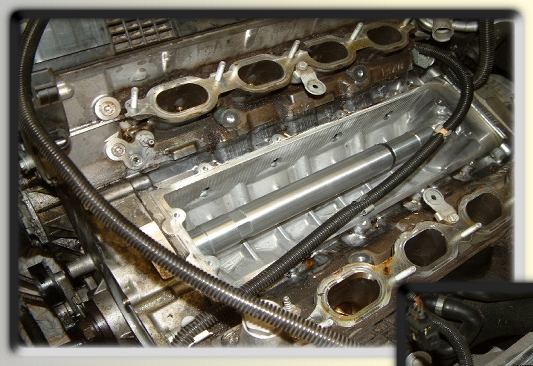

BMW ignition coils do go faulty from time to time. The ignition coils shown in figure 1 were from a 1999 BMW 323i. The vehicle came to us with a Check Engine MIL on. The technician noticed that there were ignition misfires present. Running module scan with our BMW GT1 diagnostic system confirmed the technician's thoughts. The GT1 revealed that number 4 cylinder was misfiring. The technician removed the number 4 ignition coil to inspect for any irregularities. The spark plug was properly torqued, but the ignition coil itself had signs of arcing, and the plastic housing was melted as well. See figure 1, red circles. With this discovery, the technician decided to remove all of the ignition coils for inspection. Sure enough, all of the ignition coils were suffering from the same affliction. This vehicle also had fault codes for oxygen sensors. The technician recommended to the customer that the four oxygen sensors, six ignition coils, six spark plugs, and the fuel filter to be replaced. Also recommended was updating of the DME with the latest software version. The customer authorized the repairs. After the repairs were completed, engine performance was smooth and powerful, and no fault codes returned. |

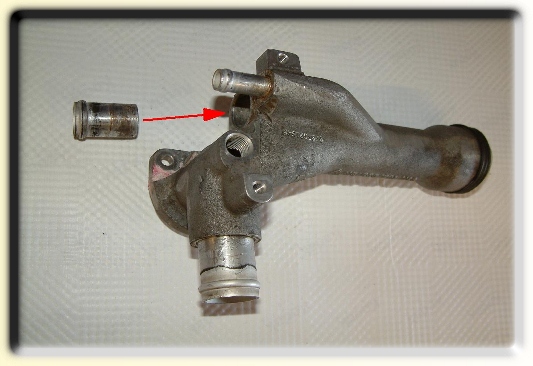

Figure 2a, Mercedes 722.6 Transmissions |

Figure 2b, Mercedes 722.6 Transmissions |

Mercedes 722.6 transmissions are pretty durable mechanically. However, the Achilles heal of the 722.6 is the conductor plate coupler. See figure 2a, red circle, shown disconnected from the transmission. The conductor plate coupler provides the connection to the wiring harness for the transmission control module. See figure 2b, black box. The issue with the conductor plate coupler is that it is prone to leaking. The transmission fluid leaks into the coupler, and creates electrical shorts. This situation can cause a check engine MIL, irregular shifting, limp mode, or damage to the transmission control module. |

In some cases, the transmission fluid can leak all the way up to the transmission control module, through approximately 3 feet of wiring. See figure 2b, red circle, transmission fluid leakage. As is the case with many european automobiles, Mercedes have very sensitive electronics. Electrical shorts or spikes can "zap" out a control module in no time. Even though fuses are in place to protect the electrical components, they don't always react quick enough. Its common to find a "zapped" out module and all fuses in perfect condition. |

Figure 3a, BMW E46 3-series model Fuel Levels. |

The BMW E46 3-series model uses two separate fuel tanks. The fuel system uses a jet system to transfer fuel from the left tank to the right tank. When fuel level irregularities come about, Our BMW technician can access the amount of fuel in each tank via instrument cluster. See the red-circled area in Figure 3a. The first three digits (015) is the amount of fuel in liters in the left tank. The last three digits (327) is the amount of fuel in liters in the right tank. 1.5 liters + 32.7 liters = 34.2 liters. The fuel capacity for the E46 model is 63 liters, 34.2 liters is equal to slightly more than 1/2 the fuel capacity. Notice the fuel gauge in Figure 3a; the needle is slightly past the half mark, so this fuel gauge is reading accurately. |

Figure 4a, Mercedes motor mounts. |

Mercedes motor mounts are filled with very thick oil. The oil dampens the vibrations from the engine. Over time, the rubber bladder containing the oil can stretch or crack, allowing the oil to spread out or leak. The result is a "sunken" motor mount. See the red height reference lines in Figure 4a. The motor mount on the right is an old sunken mount, and the one on the right is a new updated style motor mount (both mounts are for the same vehicle). Sunken motor mounts cause the engine to sink in the engine bay. This situation changes the geometry of the driveline. The result is added strain on the transmission, engine wiring harness, and hoses. also, vibrations from the engine transmit into the chassis, which can fatigue and loosen fasteners. |

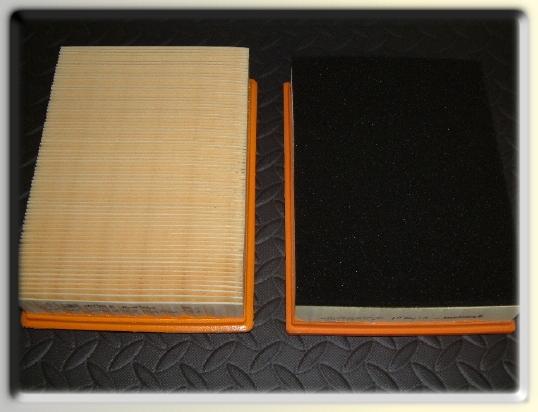

Figure 5a, BMW E39 and E46 air filter. |

There are two separate air filter designs for the BMW E39 and E46 chassis 6 cylinder engines. Figure 5a displays the two different designs. The air filter on the left is a "light duty" filter. The air filter on the right is a "heavy duty" filter with a layer of black foam attached to the underside. To avoid potential MIL (Mafunction Indicator Lamp) warnings, we prefer to install the heavy duty filters on the 6 cylinder E39 and E46 chassis cars. Under certain circumstances, the light duty filter can have a negative affect on the air/fuel mixture. The mass air flow sensor can compensate for the less restrictive filter, but this shifts the calibration closer to the limits of its operation perameters, making it easier for MIL warnings to pop up on the instrument cluster. |

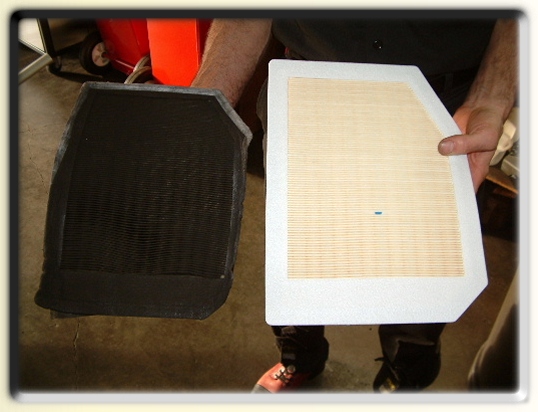

Figure 6a, Porsche 993/911air filter. |

The air filter on the in Figure 6a is an air filter from a 1995 Porsche 993/911. The filter was not replaced for quite some time, resulting in an extremely restricted filter. In fact, this filter was partially "sucked" into the airbox by the choking engine! The air filter on the right is the same filter (albeit new). Notice the white base flanges compared to the distorted flanges on the old filter. We recommend replacement of engine air filter(s) on all automobiles at no more than 30,000 mile intervals (or cleaning and oiling if its a K&N filter). Dirty air filters rob your engine of performance and fuel economy, so keep track of the condition of your air filters. |

Figure 7a, Mini Cooper convertible top side rail mechanism. |

Figure 7a is a right side convertible top rail mechanism from a 2005 Mini Cooper Convertible. The area circled in red are broken parts where the cable anchors to the mechanism. Over time the connection fatigues and fails. The result is non-release of the convertible top on the side that the cable breaks. |

Figure 7, Mini Cooper oil filter housing cap. |

The Mini Cooper oil filter cap on the right in Figure 7 is missing it's plastic cage. The plastic cage inserts into the oil filter, and can sometimes be pulled out with the filter. If care is not taken by the technician, the plastic cage can easily get discarded with the old oil filter. The oil filter cap on the left is a new cap complete with the plastic cage. Without the plastic cage in place, the spring in the cap will tear through the end of the oil filter, and possibly cause a change in oil pressure as a result. |

The Porsche 928 in Figure 8 was subjected to incompetent past electrical repairs. With older automobiles, electrical wiring problems are common. Typically, older automobiles have had a few owners, and somewhere in the history of the automobile an owner will add electronic accessories. More often than not, the electronic accessory will appear to be nicely installed from the outside. "Behind the scenes," it is common to find poorly connected wires, unorganized wires that look like a bunch of spaghetti, and accessories being powered by incorrect systems (i.e. tapping into the power for the ESP system, or ABS system for example). Tapping into certain systems to power up an electronic accessory can result in falsely activated dash warning MILs, and/or damaged control modules. Professional technicians agree that aftermarket accessories should not be installed on any high-end motor vehicle. |

Figure 8, wiring harness damage from past incompetent work. |

Long oil change intervals is a major cause of sludge build-up in engines. Figure 9a shows the sludge build-up and discoloration in the cylinder head and inside the valve cover. The vehicle in the photo is a 1999 BMW 323i with 157,936 miles. Sludge inside the engine restricts oil flow, and causes accelerated wear of internal engine components. In some areas of this cylinder head, the sludge was 1/2" thick! |

Figure 9a, Sludge build-up from long oil change intervals. |

Figure 9b is a detailed view of the same engine shown in Figure 9a. If the owner were servicing this vehicle with engine oil and filter changes every 5000 miles or less with good quality oil, the internal parts of the engine would be bright aluminum with no sludge build-up. |

Figure 9b, Sludge build-up from long oil change intervals. |

Figure 10, Separated engine oil filter. |

Figure 10 shows a separated oil filter. This oil filter was found on the same BMW engine shown above in figures 9a and 9b. A combination of a low quality oil filter, and long oil change intervals has caused this filter to break apart. Smaller pieces of the filter are likely scattered throughout the engine, which can cause a restriction in the oil galleries. Figure 10a shows the difference between a proper factory Mercedes fleece oil filter (far right), and cheap aftermarket oil filters (the two filters to the left) that are collapsed from oil pressure. If you look closely, the far left filter has the plastic end cap missing - it was stuck in the oil filter housing cap. The collapsed filters were starving the engine of oil, subjecting the engine to added wear, and shortening the engine lifespan. |

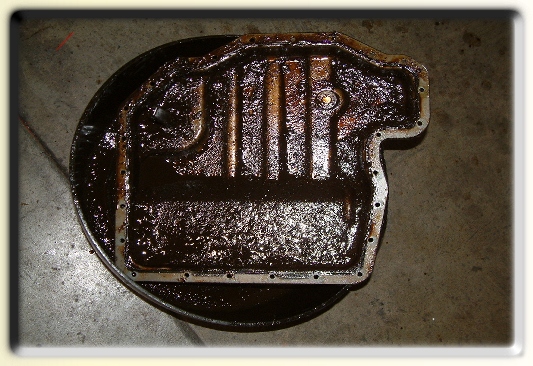

Figure 9c, Sludge build-up from long oil change intervals. |

Figure 9c shows the sludge build up in the engine oil pan of a 1999 BMW 540i. The sludge is the result of a combination of long engine oil change intervals, poor quality oil, and lack of other maintenance. |

Figure 11a shows a replacement telescopic water pipe that takes the place of the leak-prone one piece water pipe (Figure 11b). The telescopic water pipe saves about half of the labor time (huge savings over the BMW dealer labor) compared to replacing the water pipe with the same one piece pipe, which requires dismantling most of the engine. The telescopic pipe expands in place to avoid the removal of the front of the engine - significant savings in labor time. BMW dealers charge up to $10,000 for the replacement of the one piece pipe. We can install the telescopic pipe for $4000 including replacement of the water pump |

Figure 11a, E65 745i new/improved valley water pipe. |

Figure 1, BMW E46 Ignition Coils |

Figure 12, Mercedes 202 Burnt S.A.M. Circuit Board. |

Figure 12 shows a burnt circuit board on a Mercedes front S.A.M. (Signal Acquisition/Activation Module). The customer explained to us that the windshield wiper stopped in the middle of the windshield while driving in wet weather. She took the car to a non-Mercedes service center for repairs. The service center supposedly replaced the wiper motor. None of the related fasteners appear to have been tampered with, so it's questionable if the wiper motor was even replaced. Their technician tested the wiper with a water hose running down the windshield. In the process, water managed to get inside the front fuse box, and inside the S.A.M., causing the circuit board to short and melt. Since the service center was not a Mercedes specialist, they told the customer that they couldn't perform the S.A.M. replacement (a Mercedes SDS diagnostic system is needed for this type of repair). Basically, they damaged the customer's car, and told the customer that they couldn't repair the problem they caused. The customer brought the vehicle to us for repairs (we have the required SDS diagnostic system - see our Equipment page). We replaced and programmed the S.A.M. and the fuse box, and lubricated the wiper arm linkage. The wiper now functions perfectly. Lesson learned: Do not let service centers touch your car if they do not have the proper factory equipment. If a service center claims that they service Mercedes, but do not have the factory equipment, then they are not a Mercedes specialist. |

Figure 11b, E65 745i leaking one piece valley water pipe. |

Figure 10a, Separated engine oil filter. |

Figure 10b, Separated engine oil filter. |

Figure 10b shows an aftermarket oil filter that was in the process of collapsing in on itself. As a result. the engine was starving of oil. |

Figure 13, Porsche 99-09 Alternator Pulley (with Free Wheel Lock) . |

Figure 13 shows a 99-09 Porsche alternator pulley with the free wheel lock feature. The pulley locks and spins the alternator under acceleration, and free wheels under braking, and coasting. When the free wheel lock mechanism wears, the pulley will rattle (heard best at idle). In some cases, the locking mechanism can fail, causing the alternator to spin at reduced rpm or not spin at all. This condition can lead to an under charged battery or dead battery. |

Figure 14, BMW X5 Door Handle Carrier. |

Figure 14 shows a broken hinge on a BMW X5 door handle carrier (circled in red). When the hinge breaks, in most cases the outside door handle will not open the door that is afflicted. Replacement of the door handle carrier is pretty involved due to the tight confines that the part resides in, and also the number of small parts that must simultaneously fit together upon reassembly. Replacement of this part is not recommended to be performed by the vehicle owner. |

Figure 15, BMW E38 Ignition Lock. |

Figure 15 shows a broken ignition lock from a 1998 BMW 740iL. When the ignition lock breaks, it often causes the ignition tumbler to spin around 360 degrees, making it difficult to shut the engine off. The ignition lock is tricky to access and remove due to the theft-deterrant bolts that anchor the lock in place - definitely not a DIY home project. |

Figure 16, Porsche 997 Turbo Heat Exchanger. |

Figure 16 shows a leaking heat exchanger (the pink residue is dried Porsche antifreeze) from a 2007 Porsche 997 Turbo. This is one of two heat exchangers that reside on top of the engine. Access to these heat exchangers are very tight, and requires removal of the oil filter housing, removal of the throttle body and cross over tube, and often lowering of the engine itself depending on which of the two heat exchangers needs to be accessed. |

Figure 17b, BMW E90 2006+ 3 series water pump. |

Figure 17a, BMW E90 2006+ 3 series coolant thermostat. |

Figure 17b shows a faulty water pump off of a 2006 BMW 3 series E90. These water pumps are electrically operated. Over time, these electric water pumps lose performance and slow down over time, causing the engine to run hotter and hotter. |

Figure 17a shows a faulty coolant thermostat off of a 2006 BMW 3 series E90. These thermostats are electronic operated. Over time, these electronic thermostats malfunction over time (usuallt stick open), causing the engine to run cooler than it should, using more fuel, higher emissions, and typically activating a Service Engine Soon warning on the instrument cluster. |

Figure 18, Mercedes Brake Switch. |

Figure 18 shows a faulty Mercedes brake switch. Faulty brake switches can cause check engine/service engine soon warnings, ABS, ESP, BAS, and transmission performance anomalies. |

Figure 19, Porsche Oil Separator / Crankcase Vent Valve. |

Figure 19 shows a faulty/leaking Porsche oil separator/crankcase vent valve. In addition to oil leaking out of the vent valve, creating an oil mess down the face of the engine, odd noises and possibly a check engine warning can occur. |

Figure 20, Porsche 911/997 Twin Turbo Water Manifold. |

Figure 20 shows a faulty/broken Porsche 911/997 Twin Turbo water manifold. The pressed-in hose fitting separated from the water manifold casting. The red arrow illustrates the location where the hose fitting would anchor into the casting. Due to the tight confines of the location where the water manifold resides, it can take approximately 24 hours from start to finish to replace this part. Ordering this part takes some caution as well, because it is often confused with the GT3 water manifold which has an absence of the fitting above the one that separated here. |

BMW |

Mercedes |

Porsche |

MINI |